Since its establishment in 1930, HAYASHI-REPIC has continued to refine its core technologies in support of a growing number of industrial sectors.

“Our employees have diligence and tenacity. That has led to the strength of our precision technology.”

Atsumi Hayashi, President, HAYASHI-REPIC Co., Ltd.

For over 90 years, HAYASHI-REPIC has developed precision processing and assembly technology cultivated through its experience in watch manufacturing. Today, its technology is used in various fields, including semiconductor manufacturing, control systems, lighting equipment and precision tools. “Based on our experience gained through the manufacturing of a high variation of precision parts and products, HAYASHI-REPIC can offer solutions that are developed and designed from the viewpoint of users,” says president Atsumi Hayashi.

HAYASHI-REPIC comprises five divisions and the first business division provides precision processing and electronics technology. Its main products, the optical fiber-type, high-brightness cold-light lighting system ‘Luminar Ace’ and the high-brightness LED lighting system, are used in semiconductor manufacturing, liquid crystal manufacturing, automatic inspection equipment in the medical and bio industries, and image processing equipment. Another flagship product of is the ‘Hi-Matic’ series of screwdrivers used to manufacture watches, hard disk drives (HDD), mobile terminal devices, and other electric and electronic equipment.

The second division develops, manufactures, and sells cooling equipment that make use of the company’s electronic cooler technology. In addition to refrigerators and humidifiers for medical equipment, HAYASHI-REPIC handles everything from the design to manufacturing of original units according to user requests, while also developing a variety of control devices.

Established in 2010, the third division is engaged in the assembly and inspection of precision electronic equipment. Thanks to its extensive experience in ultra-high-precision manufacturing and advanced facilities, HAYASHI-REPIC has advanced into the fields of semiconductors and optical communication equipment. “Our size is relatively small, so when we work together with major companies, we make semiconductor prototypes for them or receive a small lot for high variation products that could not be done on their main mass production line,” adds Mr. Hayashi.

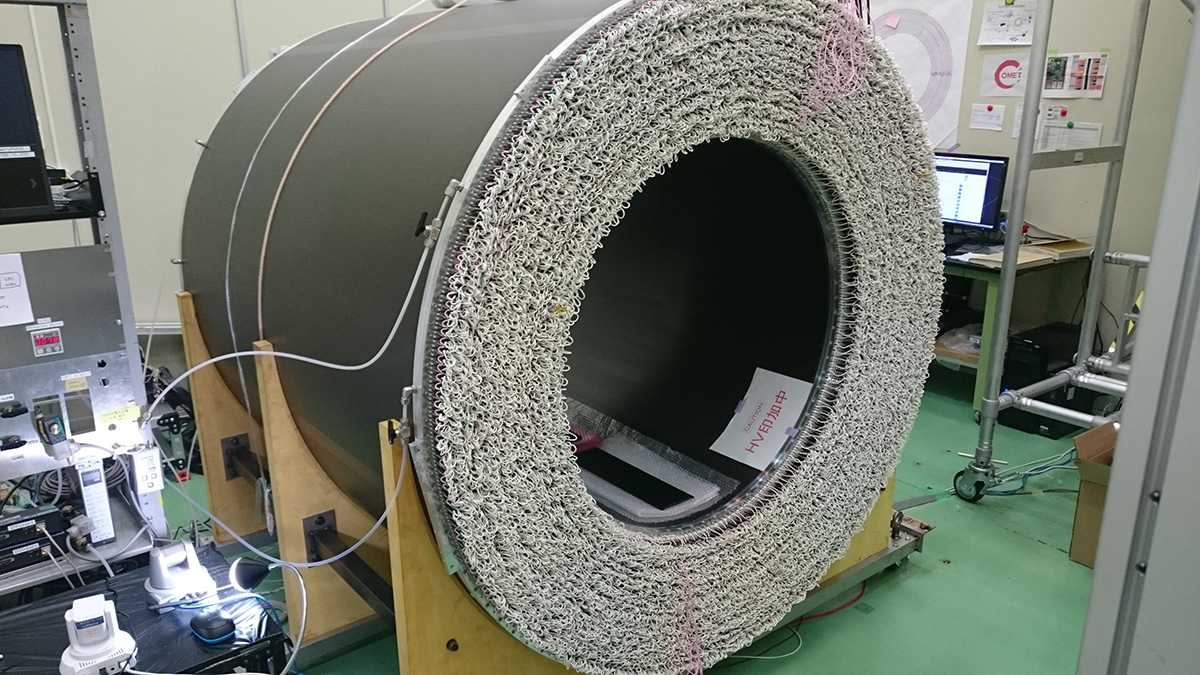

Division four handles the import and sale of industrial electronic products, such as coaxial cables transformers, and optical-related and EMC-related products. As a result of its relationship with KEK, one of Japan’s leading research institutes focused on high-energy physics and particle research, this division is also engaged in the development of particle beam detectors.

The company’s fifth division is responsible for everything from the design to the sale of automatic feeders and automatic assembly processing machines for the assembly, inspection, and secondary processing of minute parts such as electronic parts, as typified by its own product, the Dyna Feeder. In addition to the five divisions, HAYASHI-REPIC also has a manufacturing subsidiary in Hinai, Akita Prefecture, and sales subsidiaries in Hong Kong and Shenzhen.

“The strength of our company is in the precision,” says Mr. Hayashi. “Our employees have diligence and tenacity. That has led to the strength of our precision technology, as well as the attitude towards product evolution.”

0 COMMENTS