Teikoku Electric provides fully customizable canned motor pumps for a range of industries.

“When we take on a client, we hand-make each unit.”

Yoshihiro Koroyasu, President & CEO, Teikoku Electric Mfg. Co., Ltd.

Japan excels when it comes to niche B2B manufacturing markets, where small, agile and innovative Japanese SMEs can offer clients high-mix, low volume customized products. Since these markets are small, larger players normally stay away, as highlighted by Yoshihiro Koroyasu, president of canned water pump manufacturer Teikoku Electric, whose products are used in several industries such as fine chemicals, petrochemicals, pharmaceuticals, power generation and food.

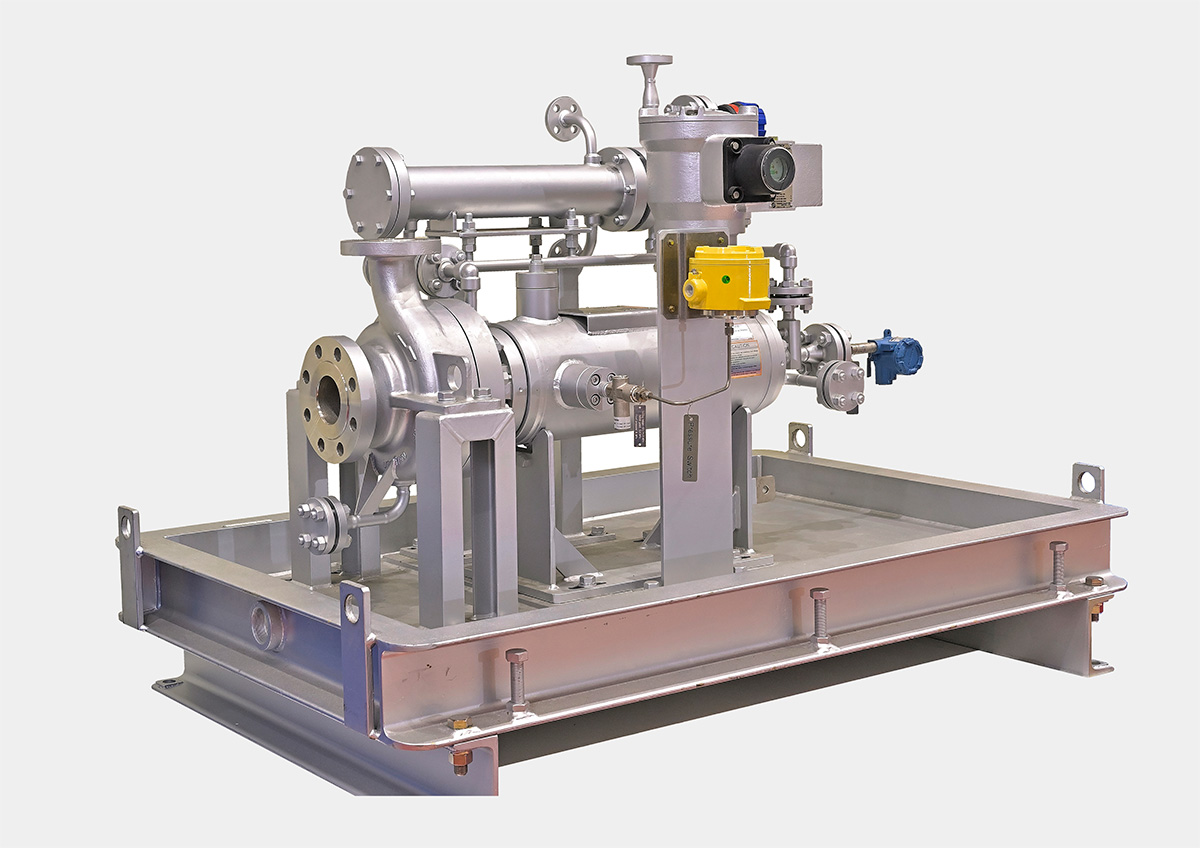

With over 50 years in the business and a proven track record worldwide, Teikoku Electric provides canned motor pumps that are fully customizable in order to meet the often complex requirements of its customers.

“Most of our clients are in the chemical industry, and their demands are not only hard to satisfy, but also diverse in nature. Often they will ask us for products that can meet American standards. Large companies do not really want to meet these demands as they find them too niche and too customized to individual clients’ needs,” Mr. Koroyasu says. “That is why when we take on a client, we hand-make each unit. We are operating on the complete opposite end of standardization. Large companies simply cannot address these kinds of highly complicated requests, and we find our clients are very happy with our customized approach.”

These days, client and industry demands are indeed largely influenced by green policies. Mitsubishi Heavy Industries, for example, has introduced an initiative involving the mixing of ammonia with coal to produce power while reducing the amount of coal. “We as a company have many years of experience in pump production, so we want them to use our pumps in their process. Specifically, we mean the pumps used to supply ammonia,” adds Mr. Koroyasu.

Teikoku Electric’s clients can also use its pumps in biomass power generation as well as offshore wind power and in the transportation of ammonia for hydrogen power. As such, Mr. Koroyasu hopes to see his company play a bigger part in the green energy revolution in the coming years.

“Unfortunately, being an SME, we are only able to acquire a tiny part of the market share for the power industry, but I am hoping that the mix of ammonia and coal that I mentioned earlier starts to take off so that we may capture a larger share of the market with our pumps. This business is an entry point for us to establish a large presence in the power industry. Biomass energy and wind power are also key points for the future of the power industry, so I can see these also becoming entry points for our company.”

One particular product that has great potential in the power industry is the company’s Type BP Vertical Boiler Circulation Pump, which can upgrade and replace wet stator-type boiler circulation pumps used in power generation stations. A major advantage is the fact that the pump requires little to no maintenance, a process that is costly and time-consuming for many clients.

“When liquid or water enters our competitor’s products, it has direct contact with the motor, and thus their motors have a short life expectancy. For maintenance, the clients need to replace the motor itself, which is significant in terms of cost. Our products are canned, so access to the motor is blocked, especially for liquids like water,” the president explains. “The life expectancy of our motors is much longer than our competitors. I would say that our competitor's wet motor pumps have a life expectancy of around 5 years, however, our canned motor pumps can expect a lifespan of around 10 years or more. That is double the amount of our competitors, and that cost saving is appreciated by our clients.”

As the company looks to grow internationally, Australia, China, the U.S. and India hold the most potential for Teikoku Electric, which already has seven overseas sites. Mr. Koroyasu adds: “We want to enhance production and service businesses at these sites as each still has extra room for growth.”

0 COMMENTS